Welding Laser Plasma Arc Processes

Welding laser plasma arc processes include welding fume capture, plasma and laser cutting tables, thermal spray operations. Each of these present unique and difficult issues that will cause a dust collection system to fail.

Welding

Two Stage Electrostatic Collectors; Venting welding fume operations poses some difficult application decisions. Years ago, the preferred method of collecting weld fume was with two stage electrostatic precipitator dust collectors. These had several advantages; they were relatively compact and were generally very effective on general ventilation applications. They could handle relatively large gas volumes through the collectors and generally were located near the roofs of buildings.

Efficiencies of general ventilation; The collection efficiency was variable depending on the velocity going through the collection plates. The lower the velocity through the collectors the higher was the collection efficiency. The same collector might have an 80% collection efficiency at 6,000 CFM and a 98.5 % efficiency at 1,000 CFM The same collector could be applied to different exhaust volumes that would vary as much as a ratio of 6:1. The higher the volume would produce the lowest efficiencies. But the same air would be re-circulated and an acceptable level could be maintained in a particular room or building. The cleaning of the precipitators were accomplished by a detergent wash system.

Loading for general ventilation; The loading for general ventilation units were from 0.1 to 0.5 grain per thousand cubic feet of volume. The washing frequency was typically once or twice a week. The presence of condensed hydrocarbons along with the fume was not a problem. Generally these would be oxidized into solids by the time the filter was washed. These collectors were generally the same ones that were applied as air filters in HVAC systems. The washing systems were designed for 1000 cycle life. This would translate to over ten years of life under these low loading conditions.

Hooded Systems; The trend was to hood the welding operations. The venting of hoods had some pronounced effects on the application of these precipitators. The load would vary from 5 to 20 grains per1000 CFM.

Effects of hooded systems; Usually the washing requirements were to wash the filter every shift or twice per shift because the load was so much higher. On a two shift operation, and washing twice per shift, the washing system had a life expectancy of less than 52 weeks.

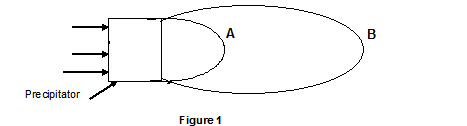

Plating; It was necessary to operate particular precipitators at lower volumes with their associated higher efficiency, because of a phenomenon called “plating”. Referring to figure 1, the precipitator will ionize the gas and the welding laser plasma arc particles. As the dust passes through the precipitator it forms a bubble type shape, containing charged particles, which were not collected on the collection plates. The gas quickly loses it’s charge. However the dust that was not collected keeps it’s charge a little while longer and loses its charge as it leaves the boundary of thebubble marked “A” in figure 1. If the precipitator has a low efficiency the bubble is much bigger as marked by “B”. This low efficiency bubble is 2 to 20X as bigger in volume than the high efficiency bubble.

Under certain atmospheric ambient conditions, this low efficiency bubble starts to grow rapidly until the whole room atmosphere is ionized and the room and all the contents become collection plates for the dust. The dust s attracted to the walls, windows, machines, eyeglasses and every object that is grounded. All the surfaces turn blackened within seconds. There have been cases where this happened after the walls were painted white. After the atmospheric conditions go back to normal the plating stops.

Bad Inlet conditions. All precipitators either single or two stage need even velocity distribution across the plates. If we had a gas stream averaging 100 fpm that would be designed to operate at 95% collection efficiency and the real velocities entering the plates varied from 50 to 150 fpm, the section at 50 fpm might have a collection efficiency of 98% and the section at 150 fpm would be running at 80%. This would mean that the overall efficiency might operate at close to 85%. This condition would cause phenomenon described above

Lower Efficiencies, caused by running at lower average velocities were common. In the example above the collector might be selected to run at 125 fpm and an average efficiency of 85%. Plating may be produced because of these lower velocities and lower collection efficiency. As a result, many collectors were purchased based on volume and the supplier’s guaranteed higher collection efficiencies. There were practically no way to specify the collectors except based on supplier claims. Velocity was not a good criterion. Some collectors at relatively higher velocity and longer sets of collection plates would achieve the same result as a collector with short plates and a slower velocity.

Electrical Controls; To further aggravate the problem improper electrical controls were offered. Some operators interpreted SIC controls to mean arcing was not allowed. To eliminate the arcing across the plates, they lowered the voltage controls to halt this sparking. Unfortunately the voltage was lowered so much that the particles were not charged. There were cases where the metal pre-filters were more efficient than the precipitators.

Insulator Coating; The main collection plates are at ground in a two stage electrostatic precipitators. The charged particles will be attracted to the lower voltage intermediate voltage level plates and to the grounded collection plates. The insulators were also at ground level and some of the dust (a very small percentage) stuck to the surface of the insulators. This was a very strong bond and the spray cleaning systems could not keep these insulators clean. Eventually they were coated badly enough that the power supply could not keep the charging electrodes to ionize the gas and the particles. To correct this problem required a major overhaul of the precipitator. The charging electrodes were made of very fine wires and would eventually break and require replacement. Most electrical maintenance men were not familiar with high voltage supplies and maintenance was neglected.

Innovations in Design; In the late 70’s, two stage precipitators with pressurized insulators and more rugged washing systems were introduced. The insulators were subject to a gas stream that entered the collection compartment at a higher velocity than the collection velocity across the plates. This protected the insulators from charged particles. The charging electrodes were made heavier to give much longer charging electrode life.

These innovations increased the collection costs with electrostatic collectors to the point where cartridge dust collectors introduced at the same time were more economical to purchase and operate.

The advantages of the electrostatic collectors were:

The pressure drop was constant and usually low.

They could collect liquid droplets.

They had the potential of long periods of service without maintenance.

Cartridge Dust Collectors

With the development of cartridge collectors, another method of collecting fume dusts became available. The standard design pulse jet fabric collectors with cylindrical bags did not work because the cleaning systems propelled dust through the cake of adjoining rows of bags during the cleaning cycles. In the late 70’s and early 80’s thousands of cartridge collectors were applied to both hooded and non-hooded ventilation systems.

Problems developed in many systems after the mid eighties. High-pressure drops and short cartridge life developed in many systems. The causes were one or more of the following:

The presence of thin films of oil on the surface of the parts that were welded. When electrostatic powder coating finishing systems were widely applied to reduce or eliminate hydrocarbon generation from paint systems, the faces of steel parts required protection from oxides on the surfaces. During the welding process condensing hydrocarbons were liberated and swept up into the ventilating systems and their associated collectors. One of several results followed:

a) The solids to liquid ratio was so high that the dust blotted the liquids and the collection system was not affected by the liquid droplets.

b) The solids to liquids ratio was in range where the powders and hydrocarbon mixture formed a paint and the collection media was gradually plugged. This could take days, weeks or months, but the net effect was the cartridges had to be replaced or laundered pre-maturely.

c) The solids to liquid ratio was so low that liquid wetted the cartridges and they were plugged as in (b) above. Even in cases where the coating was barely discernible, this could occur.

A case in point was in a plant making stainless steel mufflers. The metal was washed after forming and the load in solids was 0.02 grains per 1000 CFM, the pressure drop rose in a six month time period. The re-enforced cellulose media would be air-dried and the pressure drop would be reduced from six inches to 0.3 inches after the elements were installed. After 4 months the pressure drop went up to six inches. After washing the pressure drop went down to 0.8 inches. The next washing cycle came two months later and the pressure drop returned to 1.2 inches. It was less expensive to replace the cartridges than to wash them in such a short interval.

Washing cellulose media cartridge elements: After each washing, the media is wetted, the permeability of the media diminishes, even if no dust remains at or below the surface of the media. The wetting causes the media to matt. If oil wets the media it is a good blotter and the fibers may grow. This causes the pressure drop and base permeability to decrease.

Other media are available that can be washed and are not wetted by oils. These are referred to as oleophobic media. This is a coating on the fibers that does not change the permeability. Otherwise they will be called washable. Often they can collect a mixture of fumes and hydrocarbons because the fibers do not swell.

Treated Spun bond medias are widely applied. Some of these are excellent choices but have limitations. For instance, with tight pleats, the top of the pleat may squeeze so the media in that portion of the pleat may make contact on the clean side when the pressure drop rises. On some applications, over 80% of the pleat of the media may not be effective. The remedy is one of the following.

A) Provide pleats with wider spacing and make them shorter in depth. This will allow full use of the media available in the filter element.

B) Provide a media that has stiffness and will not collapse on itself.

C) Provide a laminated media with the clean side backing very open so that if the pleat squeezes there will be flow through the media.

De-agglomerating dust; Normally we would run a properly designed dust collector at 1 to 1.5 inch water column pressure drop. Sometimes a system will only stabilize at a higher reading (E.G. 3 to 4 inches). One possibility is that it takes 3 to 4 inches to cause the dust to agglomerate and fall to the hopper. It may be de-agglomerating when you pulse at lower pressure drops. In that case off-line cleaning should drop out the de-agglomerating dusts. Some dusts are more susceptible to this phenomenon than others. Often, they put an anti-rust wipe on the material being cut. If it contains ceramics then we will have this problem.

Fume Generating Processes Similar to Arc Welding and Gas cutting

Thermal Deposition Processes

Spray Coating The first type was a flame spray coating machine. These fed a material into a high heat gas torch. The temperature achieved was so high that feed material would produce a material in gaseous/liquid form that started to condense into molten droplets. Though the process is not understood, it is presumed that some of the adhesion was from a nuclear bonding, in addition to the cooling of the molten droplets on the piece to be coated. There were some materials that were too porous and there was limits to the thickness of the coating. The over-spray that did not adhere varied from about 5 – 20% of the material fed into the coating generating gun. The over spray was generally collected by medium pressure air washer scrubbers at a 99% collection efficiency.

Plasma Arc Spray To get smoother surfaces and better adhesion to the target surfaces, an electric arc was added to gas flame. This produced much higher temperatures in the gun at the point where the powder or wire feed entered. It generally produced more over spray (10%-40%). This over spray was much finer and would lose its ability to stick and adhere to surfaces. This over spray was too fine to be collected efficiently with air washer wet scrubbers. Fabric or pleated cartridge collectors were necessary.

One serious problem was encountered. This involved residence time of the dust between the gun and the media collection surfaces. In a system installed in 1975, on a plasma arc spraying machine for coating electrical capacitors. The process was coating plastic surfaces with metal. The cartridge collector filter elements, venting the over spray, plugged up in less than ten minutes. The six cartridges each with 50 square feet of filter, (300 sq. ft. total) received less than 250 grains of dust. The dust collector was connected within 20 inches of the gun. The over spray dust adhered to the media surface and blocked the pores.

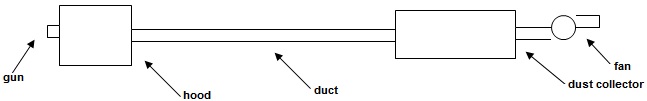

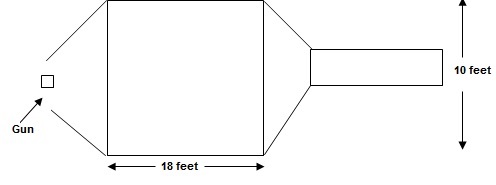

Through experimentation and field experience it was determined that if the dust stayed in the gas stream for relatively long periods of time, it would lose its ability to coat the media. Depending on various factors such as the feed rates of gas, solids and the arc current, this time varied. It varied from 0.5 to 1.0 seconds. Referring to the next figure, the residence time will be analyzed.

The part to be coated is placed in a hood with the gun at the front of the hood. The hood is 6 foot long and is rectangular with a 4 x 4 opening. The face velocity of the hood is 350 feet per minute. The duct is sized at a 2500 feet per minute duct velocity and the duct is 15 feet long. We will assume the back of the hood has a transition 2 foot long, designed like an evasé to have uniform velocity distribution.

1) Time to travel through the hood 6 ft / 350 FPM = 0.017 seconds

2) Time to traverse duct to the collector 15 ft / 2500 FPM = 0.006 seconds

Residence time = 0.017 + 0.006 = 0.023 seconds.

The flow through the system is 350FPM x 16 sq. ft. = 5600 CFM

To re-design collection for longer residence time the length of travel in components are altered and the velocity can be modified. The hood is the first to be looked at.

3) The hood would be made 10 foot wide with the same 4 foot by 4 foot opening for the gun and part. The velocity in the wide part of the hood would be 5600 CFM / 100 sq ft = 56 FPM

The residence time in this portion of the hood would be 18 feet divided by 56 FPM = 0.32 seconds.

4) The duct could be extended to 200 ft by putting in ductwork in a “serpentine fashion” and enlarged to drop duct velocity to 1,000 FPM. The residence time in duct would be 200 feet/ 1000 FPM = .0.20 seconds

The residence time of the system would be 0.32 + 0.20 = 0.52 seconds.

High Temperature Cutting Processes

This high temperature flame coming from the gas gun proved to be an excellent improvement in flame cutting. Instead of jagged edges near the cut, it became much smoother and for most applications it did not require smoothing the edge or the operation was very quick. With digital cutting machines the precision rivaled other cutting processes.

Plasma cutting and laser-enhanced cutting are in common use. The type of dust produced runs the gamut from arc welding to that of metalizing operations. Most dust is more similar to venting systems for arc welding operations, but to get some cutting characteristics the temperature and flow in the gun are adjusted. This may produce a dust that is prone to coat surfaces and media. When this happens the residence time requirements may be in the same range as the electro deposition processes. Laser cutters work well with 1 second residence time. Some flame cutters have been applied to non-metallic pieces such as wood and plastics. These dusts can contain tars, and oils from non-metallic parts and the collector media can get plugged easily, within a few seconds. With metallic parts, the oils can be an imperceptible film on the metal or originate from the compressed air compressor. In that case, a low-pressure scrubber may be a good choice. Roll filters with replaceable media or a self-feeding pre-coat material system have been employed.

It is crucial to have the correct airflow at initial start-up. Too much airflow will reduce residence time and cause the painting effect. Install a control damper in the main duct and use an approved method to accurately measure the exact airflow. Use the damper to choke the system if needed.

Recently, it has come to our attention that some plasma cutting processes are throwing out the 1 second residence time rule of thumb. Either the process temperature is being cranked up so high that the molten metal atoms still don’t have enough time to form molecules or the dust concentrations are so low that the atoms never get a chance to collide with one another in the laminar flow of the duct system. In these cases, finding the correct residence time

is almost a trial and error process. A new product has come on the market, called a Quencher, which is inserted in the ductwork as close to the source of dust as possible and no less than 10 duct diameters upstream from the collector. This device imparts a high energy multi-directional swirl to the air stream which cools the metallic atoms, accelerate their oxidization, and forces them to collide together and form molecules which can safely be collected without the painting effect.

Use the links below to obtain more information on welding laser plasma arc applications.

More… Quencher spark arrestor

Get help… Consulting and troubleshooting