OLD Technology

Old dust collector technology represents 85-90% of today’s dust collection market, and is sold by all the big conventional suppliers. These dust collectors can handle most dust loading and high temperature (up to 400 degrees F.)

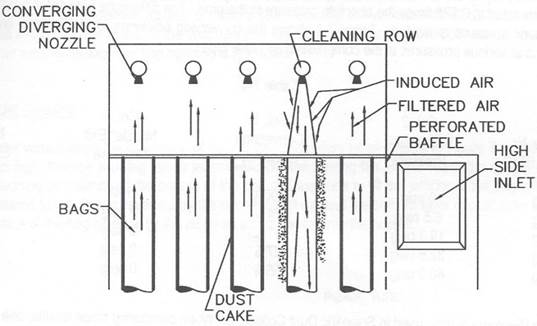

Circa 1963; compressed air powered cleaning by rows of bags is introduced, with venturi accelerated pulse jet to project to the bottom of bag. The filter ratio (air-to-cloth) of 10:1 or less, dependent on the application. Dust penetration (puffing) was unacceptable for re-circulation to the work area.

Circa 1971; a “generic” design, modified to use 10-foot bags was marketed to be competitive. Major design flaws led to selection of dust collectors strictly by filter ratio (air-to-cloth). Most operate at 4-6:1 ratio. Pressure drop is 6-8”wc. High compressed air consumption with higher cleaning frequencies are needed to be effective. High velocity dust impinges on adjacent bags which are too close together. The entire industry copied the same design and very little has changed to this day.

Old Conventional Technology

NEW ADVANCED TECHNOLOGY

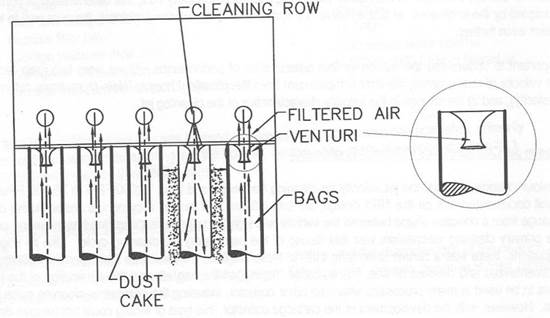

Circa 1979; NEW “Advanced Dust Collector Technology” first appeared. It is a proven technology but little known or understood in the industry. This new technology produced 95% less dust emissions, allowing for safe re-circulation to work area, thereby saving energy costs. Other startling benefits are 25-40% lower power consumption, 50-80% lower operating and maintenance cost, and a 30-40% smaller footprint.

This is accomplished by having no venturi to restrict flow, a low velocity – high volume pulse-jet This results in a gentle but powerful cleaning pulse, complete filter cleaning, 200% increased bag filter life, and needing half as many bags. High side inlet eliminates “can velocity” and running the dust collector at 18:1 filter ratio, independent of process and dust loading. Supersonic nozzles produce a very high energy cleaning pulse and only 1/4 compressed air consumption.

Circa 2003; Ultra-Flow, by QAM, introduced the 6th evolution of the new advanced dust collector technology. The cleaning system is enhanced and dust distribution through the dust collector improved. The result is lower operating pressure drop and even longer filter life. Baghouses will run at 1.5- 3”wc(max) pressure drop.

For more information… Comprehensive Dust Collection Course

Find out more about NEW Technology… Advanced Technology dust collectors

Advanced Dust Collector Technology