New technology dust collectors have corrected major design flaws of common conventional dust collectors.

Design flaw #1 for conventional designs:

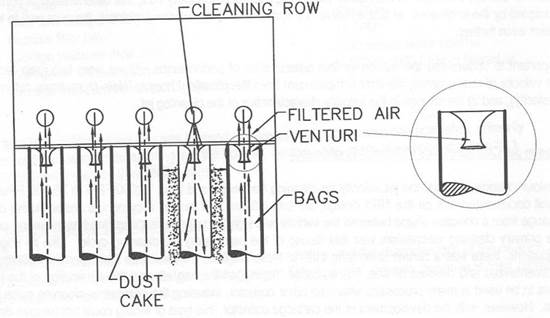

Conventional designs with cylindrical bags propel the dust from the rows of bags in process of being cleaned toward the adjoining rows in the filter mode. This high speed jet (between 350 and 400 ft/sec) drives the dust through the filter and filter cake, partially blinding the bags and reducing dust holding capacity by 80-90 percent with dense dusts. To operate at reasonable pressure drops, the potential filtering capacity of the bag is reduced by up to 80%. This high velocity dust also raises outlet loading above 100×10-4 grains per cubic foot.

The new technology design reduces the exit velocity from the bag to between 190 and 250 ft/sec depending on gas density. This keeps the permeability of the media plus filter cake to a few percentage points higher than a new bag. It typically holds several times more dust between cleanings, even at filter ratios of 15 to 20, compared to conventional designs.

Design flaw #2 for conventional designs:

The filtering capacity of the filter element is limited by the reverse air volume generated by the cleaning system. The reverse air volume is also based on the diameter of the venturi at the entrance of the bag. This, for a four inch by 1.875 diameter throat bag is only 20% of the area of the opening at the top of the bag.

The new technology dust collectors remove the restrictive venturi used in conventional designs and opens up the opening by 4 to 5 times. This increases the cleaning volume while reducing the pulse jet speed by 3 to 3.5 times. Half of the bags are removed and replaced with new bags and cages with the venturi eliminated. The rest of the bag openings are plugged and no longer used.

Other considerations for advanced new technology dust collectors

When these changes are made, the fine dust which formerly bled to the outlet is collected on the bags and ejected to the hopper. Because it is so fine, the vertical flow entering to the bag compartment, from a hopper inlet, would prevent this dust from falling into the hopper. This is the effect of upward “can” velocity.

The retrofit design removes half the bags from the collector. The dusty air enters from the bottom and also through the opening in the center of the bag compartment. This reduces the upward can velocity coming from a hopper inlet to a level 70 – 80% less than before the modification. Now the fine dust falls into the hopper unimpeded. It is equivalent to putting a high inlet in the center of the collector.

95% of the time, the collector will pass the initial engineering review. A report will be issued for your approval, before any fabrication of components begins.

A normal compressed air requirement, for contemporary designs, is 0.9 to 1.2 SCFM of compressed air per 1000 CFM of filtered air. Advanced new technology dust collectors designs are only (0.328 x (0.9 to 1.2) = 0.3 to 0.4 SCFM per 1000 CFM of filtered air.

Based on an average system requirement of 10 inches water column, a two inch reduction in pressure drop across the dust collector would reduce power consumption in the exhaust fan by 20%.

More information… New Advanced Technology Dust Collectors